Liquid-Solid 3D Printing Boosts Robot Capabilities

-

-

slice.mit.edu

- 1

Filed Under

Recommended

Although 3D printing is revolutionary, creating robots that way has been costly and time-consuming. Now researchers at MIT’s Computer Science and Artificial Intelligence Lab (CSAIL) have devised a way to print solids and liquids simultaneously, an advance that makes fast robot printing a reality.

This process, called “printable hydraulics,” uses an inkjet printer to build many layers of material that’s less than half the width of a human hair – one drop at a time. After each layer, a high-intensity UV light solidifies some materials while leaving the liquid intact.

“Making robots has traditionally been a labor-intensive and time-consuming process, but it doesn’t have to be,” says lab director Daniela Rus.

Before this breakthrough, 3D printing only created solid materials. The CSAIL printer – a Stratasys Object260 Connex – wasn’t even built to use liquids in the process. The researchers hacked the machine and inserted a different computer chip in the cartridge holding their liquid of choice – the machine’s cleaning fluid. The 3D printer was essentially tricked into printing liquid instead of plastic.

This enables complex designs to be created faster and cheaper.

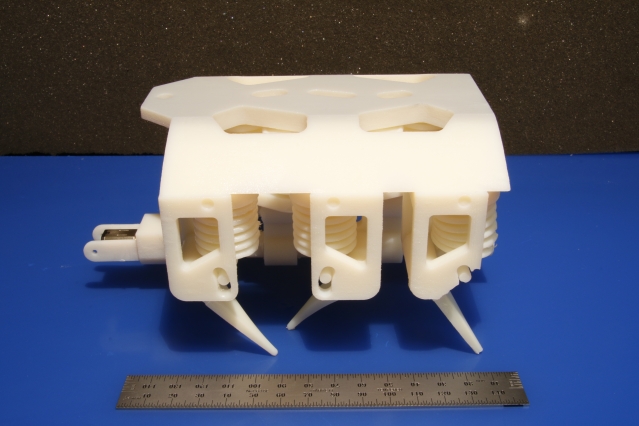

The result was a tiny six-legged plastic robot that shuffles like a caterpillar, but its implications are massive. Previously, robots took much longer to 3D print, but the team at MIT completed the process in 22 hours. All they had to do was slap a battery and a motor on top, and it was able to walk independently.

The motor spins a crankshaft, which pumps fluid to the robot’s legs. Several 3D printed bellows use the fluid pressure if that pump as a mechanical force to propel the robot’s legs to move.

“This project gets us even closer to being able to 3D print a functioning robot that can walk right out of the printer,” Rus said.

This advance unlocks the potential of creating machines that can complete household chores, or enter hazardous areas – like burning buildings. Or as Rus says, this can enable robots to do anything from measuring radon to playing chess.

Next, Rus and her team plan to improve the 3D printing process, and thus expand its manufacturing capabilities. Printing hydraulics gets closer to printing all components of a device in one step.

“We would like to accelerate the printing process, which actually depends less on our particular technique and more on the physical capabilities of the printers themselves,” said Rus.

Comments

Nicky

Thu, 10/13/2016 12:57pm

All they had to do was slap a battery and a motor on top and printing hydraulics gets closer to printing all components of a device in one step.

Thanks