Are You 3D-Printing with Fair-Trade Filament?

-

-

slice.mit.edu

- 4

Filed Under

Recommended

From the rubble of refuse produced in his native city of Pune, India, Pai has grown his first startup after college: Protoprint. Training waste pickers—as they are called there—to gather specific plastic products in the dump, Pai’s company uses the found bits to create plastic filament for 3D printers.

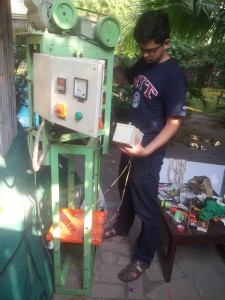

To do so, he uses two machines, affectionately called FlakerBot and ReFilBot, which he built with lowcost parts with the help of a local machinist. “The Flakerbot is a compact machine that uses a rotating 5HP shredder to ‘flake’ the HDPE bottles we put through it,” Pai told Make Magazine. “The RefilBot is a compact extruding mechanism that uses a rotating screw conveyor to transport the flakes through a ‘cooking’ process that melts it before extruding it to 3mm filament. Our machines are designed to be low-cost, safe, and easy-to-use in order to better integrate with the waste pickers current supply chain.”

Those collecting the plastic earn on average 15 times more than they would collecting traditional recycled goods. Pai will sell this fair-trade filament, which is essentially like printer cartridges for 3D printers, to 3D printer wholesalers and individuals worldwide.

Pai conceived of Protoprint as an undergraduate during his work for MIT’s D-Lab. Like many other D-Lab alumni, Pai’s goal is to use innovative technology to improve the lives of people living in poverty.

A world without waste-pickers would be nice, he says. “That’s definitely the end game. Ideally, society as a whole will move towards a more sustainable waste management model that will reduce the amount of waste plastic in dumps.”

Pai is working alongside SWaCH (Solid Waste Collection and Handling), a nonprofit in Pune, which is India’s seventh-largest city. If he can perfect his two recycle-bots to be easily assembled and handle large volumes of plastic without breaking down, Protoprint can grow.

“We are exploring a micro-finance model to allow waste picker communities to build the machinery locally, but we are still a ways away from that,” says Pai. “In terms of the technology itself, we are committed to making it open and available and are already working with a few organizations abroad (mostly in South America) to modify our technology for local use.”

Pai is also networking through the Ethical Filament Foundation, a UK nonprofit with the aim of standardizing quality of 3D filament while assuring customers of its fair-trade source.

Protoprint sells four colors of filament in two sizes. It is made of acrylonitrile butadiene styrene and high-density polyethylene, material typically found in durable plastic containers like shampoo bottles.

Apart from the enthusiastic response he has received in his community, Pai is earning international acclaim for his work. He is a current D-Lab Scale-Ups fellow and was named a Echoing Green fellow in June, offering him $80,000 to continue his work.

Comments

pipi

Wed, 08/06/2014 1:09pm

video??

Sharang

Tue, 01/19/2016 12:00pm

Here's a slightly more updated video - https://www.youtube.com/watch?v=QE1uHxIzU5E

Balıkesir Haber

Fri, 08/15/2014 11:20am

For Video thanks.

Nicole Morell

Wed, 08/06/2014 1:13pm

Here's a video of the process http://youtu.be/MOkB6PJLaH8