Sloanies Aim to Convert 100% of Sanitation Waste

-

-

slice.mit.edu

Filed Under

Recommended

“We immediately realized we had all come to learn how to build businesses that can solve massive social problems,” Stradley remembers. The business that would eventually come out of that conversation is Sanergy, a company offering hygienic sanitation solutions, waste conversion, and job opportunities in Nairobi, Kenya.

Developed as part of 15.375 Development Ventures—where students are challenged to create an innovative solution for a problem faced by one billion people—Sanergy relies on a sanitation value chain to address the sanitation crisis that affects over two billion people. The team chose sanitation issues in part because each had firsthand experience.

“David taught English in China and saw how a lack of sanitation puts populations at risk. Ani grew up in India, where his family has a biodigester to convert cow manure into energy and I had worked in post-Katrina New Orleans and saw the devastating effects when municipal service delivery systems are broken,” Stradley says.

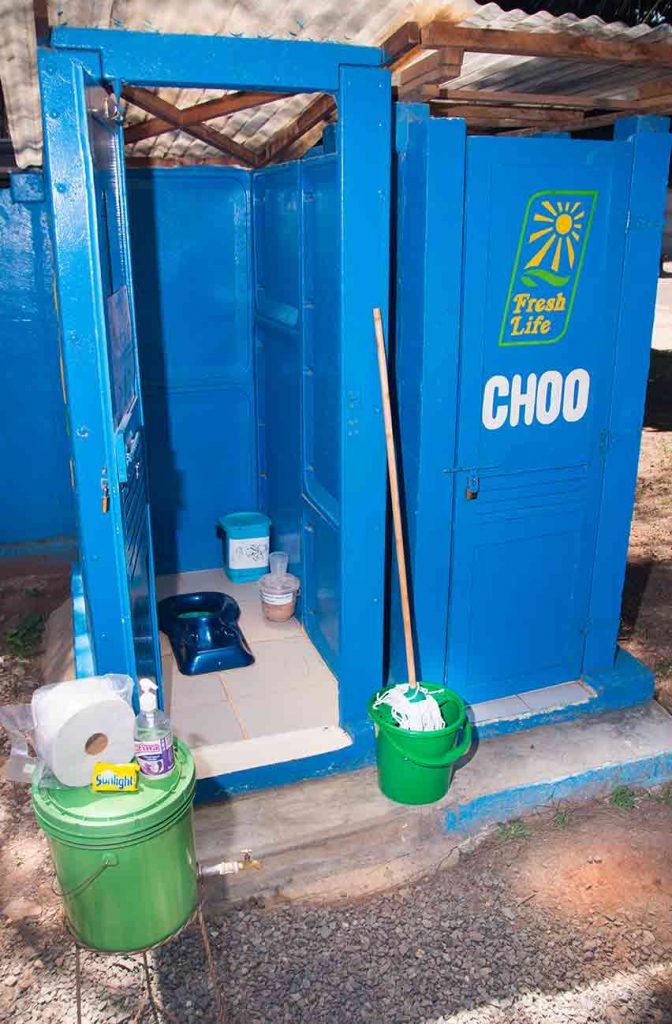

Sanergy’s sanitation value chain starts with a system of pay toilets, known as Fresh Life Toilets (FLTs), which are operated by franchisees who charge for use. The FLTs are serviced regularly by Sanergy employees with waste cartridges collected and transported to a processing plant outside of Nairobi. The processing plant works to close the loop on the value chain with end products that are created as Sanergy converts 100 percent of the waste it collects. These products are biogas, high-quality fertilizer, and a new product—sustainable, insect-based animal feed.

Black Soldier Flies are the key ingredient to the new animal feed in more ways than one. As larvae, the flies feed off the collected waste and break it down by 50 percent. What’s left of the organic waste is used for compost, and when the flies mature, they are collected and dried to be used in the animal feed. The feed is of higher-protein content and more sustainable than the fishmeal commonly used by local farmers. “Processing of the waste adds value by producing high-quality agricultural inputs that improve outcomes for Kenyan farmers and addresses food security challenges,” Stradley explains.

Today, Sanergy serves 55,000 people a day through a network of 1,295 FLTs across Nairobi, removing over 3,700 metrics tons of waste from the community. Franchise and employment opportunities with Sanergy have created over 900 jobs.

The company has plans to grow globally while exploring ideas to improve communities they already work in. The company is currently testing a pit-emptying system since 80 percent of sanitation facilities used by the urban poor in Kenya are shallow pit latrines. These latrines need to be emptied frequently and there are few places to dispose of the waste, which can end up in rivers. Sanergy is testing central pit disposals that they will service and use to convert waste, helping to clean and protect local water.

“The insights that we garner from this will give us a better understanding of how we can sustainably remove 100 percent of the waste from the community,” Stradley says. “We’re always developing ways to reach everyone with safe sanitation.”